About the skeleton: How is it composed? Why is it broken?

The skeleton is the most basic and important first step in the formation of the doll.

The broken skeleton is unlike any other problems that may arise with the doll, like cracks in the skin of the TPE or staining can be easily resolved. If the skeleton is broken, the customer can most likely only throw away the doll. After all, some damage cannot be solved even if it is returned to the factory, and the freight cost is better than buying a new doll. If it’s just a loose joint in the hand, perhaps it can be returned to the factory for some localized treatment. Just like doing surgery, cut a large hole in the TPE and process the skeleton.

But it is still necessary to rely on the specific situation of the doll damage, not all dolls have the possibility of returning to the factory to “come back from the dead”.

Problems with the skeleton are really annoying, not only affecting the experience but more critically, if the damage is so great that it can not be used, such a large doll in the home to take up space, really disturb daily life. In general, the skeleton damage caused by the production of the doll, the customer can get a brand new doll as compensation, this situation is relatively optimistic. But what if the skeleton is only problematic after a period of use? This is related to the usual personal storage methods, but also more related to the quality of the doll skeleton itself.

In general, most cases of loose doll skeletons are due to broken welding points or loose screws, because the way to connect the various joints is either welding or screws. There is a very simple way to determine the cause of the loosening, if the loose limb can wobble in multiple directions, it is possible that the welding point is broken; if the limb is wobbling in one direction, the screw is off.

In order to eliminate any situation that may cause the skeleton to come loose, SEDOLL has optimized and upgraded the raw material and processing method of the skeleton.

- The welding of the skeleton is upgraded to automation, reducing the instability of manual welding.

2.The screw installation is also upgraded to automation, and the parameters are precisely adjusted by the machine to unify the tightness. Get rid of the original manual installation, it is difficult to keep the same tightness by experience installation. In addition, the screw kit is also upgraded to use the advanced version in order to enhance reinforcement.

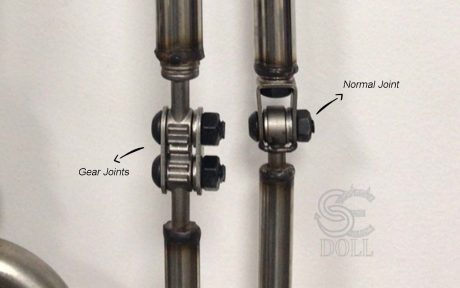

3.Arm joints use gears instead of normal joints. The contact area between the two metal surfaces of normal joints is too large, and the joint will become looser and looser due to frequent friction during long-term activities. The gear connection method reduces the contact area due to the uneven surface of the gear, which greatly reduces the friction and prolongs the service life.

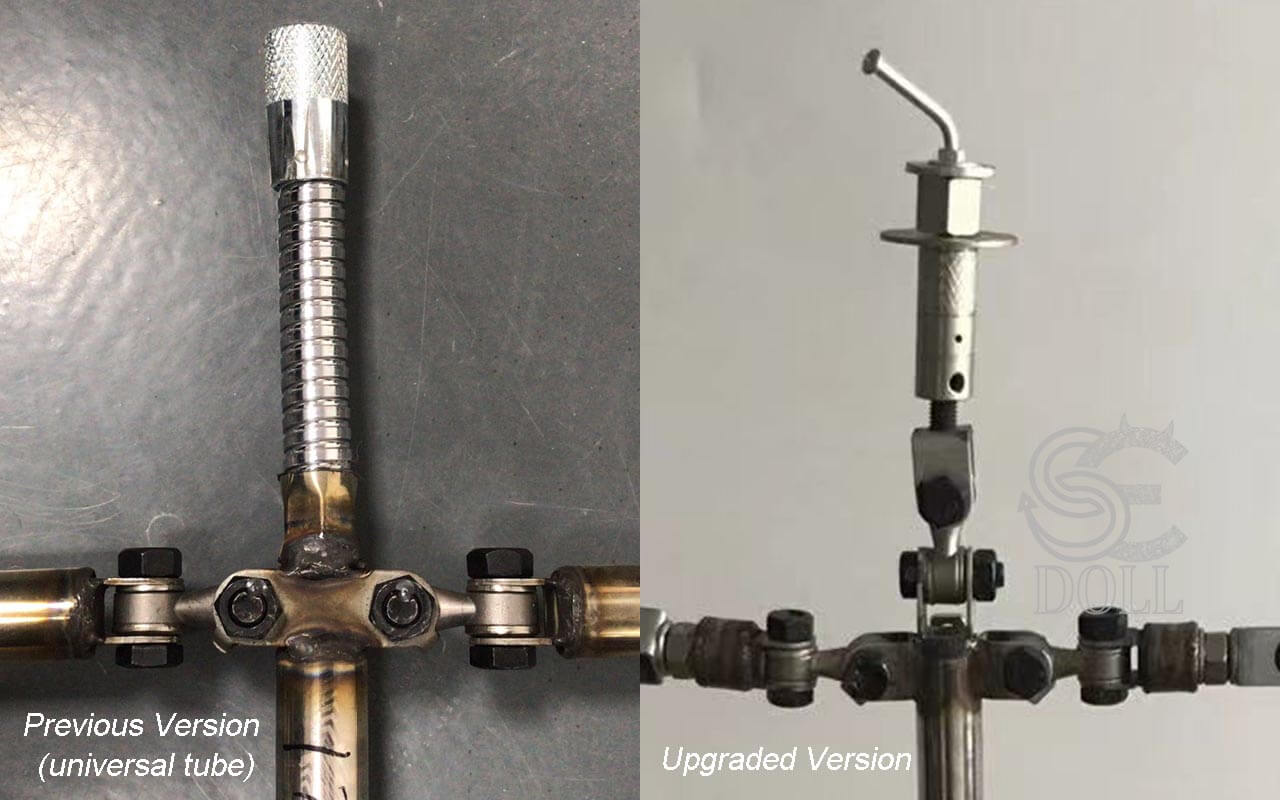

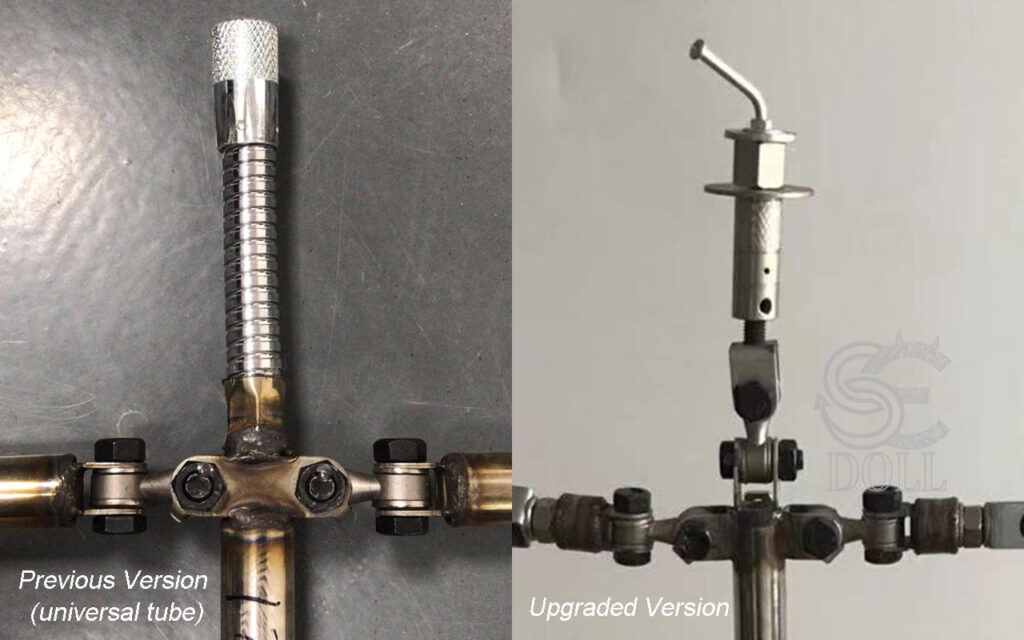

4.Neck using steel pipe instead of the universal tube. The universal tube is too soft and easy to damage, instead, the steel tube is more durable and can achieve the same effect of the activity.

Know More Blogs of SEDOLL